I was recently trying to build a small deck behind my house using traditional lumber. I say “trying” because after purchasing 37 pieces of what I thought were straight boards, I discovered that at least 36 of them had developed scoliosis. One had aspirations to be a boomerang.

This is because lumber, while technically “wood,” is actually a living creature that continues to move long after it has been cut, dried, and sold at a price that makes gold look like a bargain.

If you’ve ever framed with wood, you know the fun of “crowning,” “sistering,” “shimming,” and other charming words that basically mean “fixing things that should have been straight in the first place.” Also, don’t forget the joy of mold, termites, and that special sound it makes when it warps in the sun — the sound of your budget screaming.

Which brings us to cold-formed steel — or as I like to call it, The Metal That Never Lies.

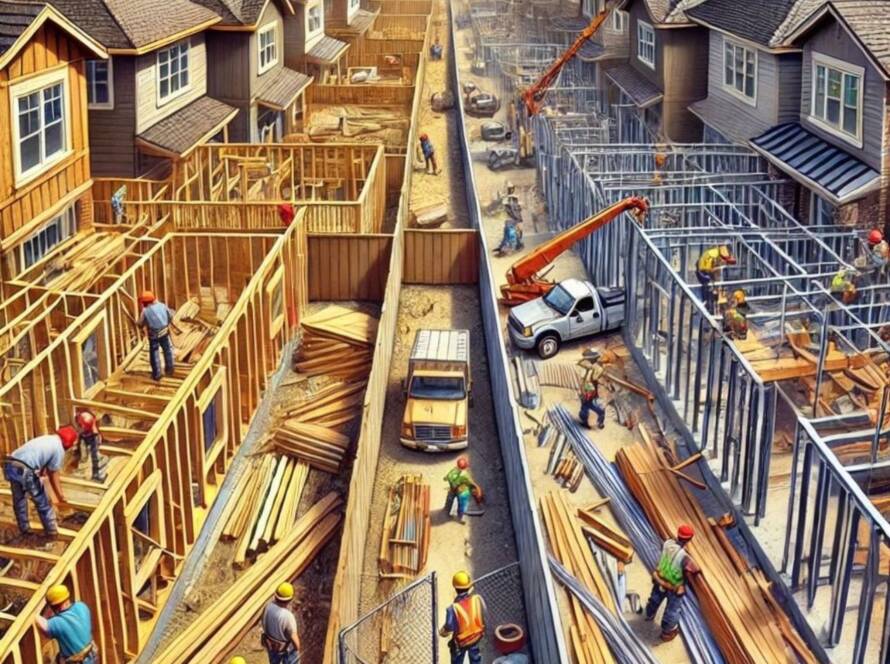

Cold-formed steel doesn’t twist, warp, shrink, or develop mysterious black spots that smell like a wet dog. It’s strong, straight, and engineered to precision — which is more than I can say for my last three attempts at cutting a 2×4. And when it’s prefabricated, it shows up on site ready to go, like a well-behaved student with perfect attendance.

With prefab cold-formed steel, you get faster builds, less waste, lower labor costs, and zero arguments with your framing crew about whether the wall is “close enough.”

So if you’re still building with lumber, I suggest you either invest in a lumberyard or start carrying a large supply of ant spray and holy water.